Semiconductor Hiring Trends 2026: What to Watch Out For (For Job Seekers & Recruiters)

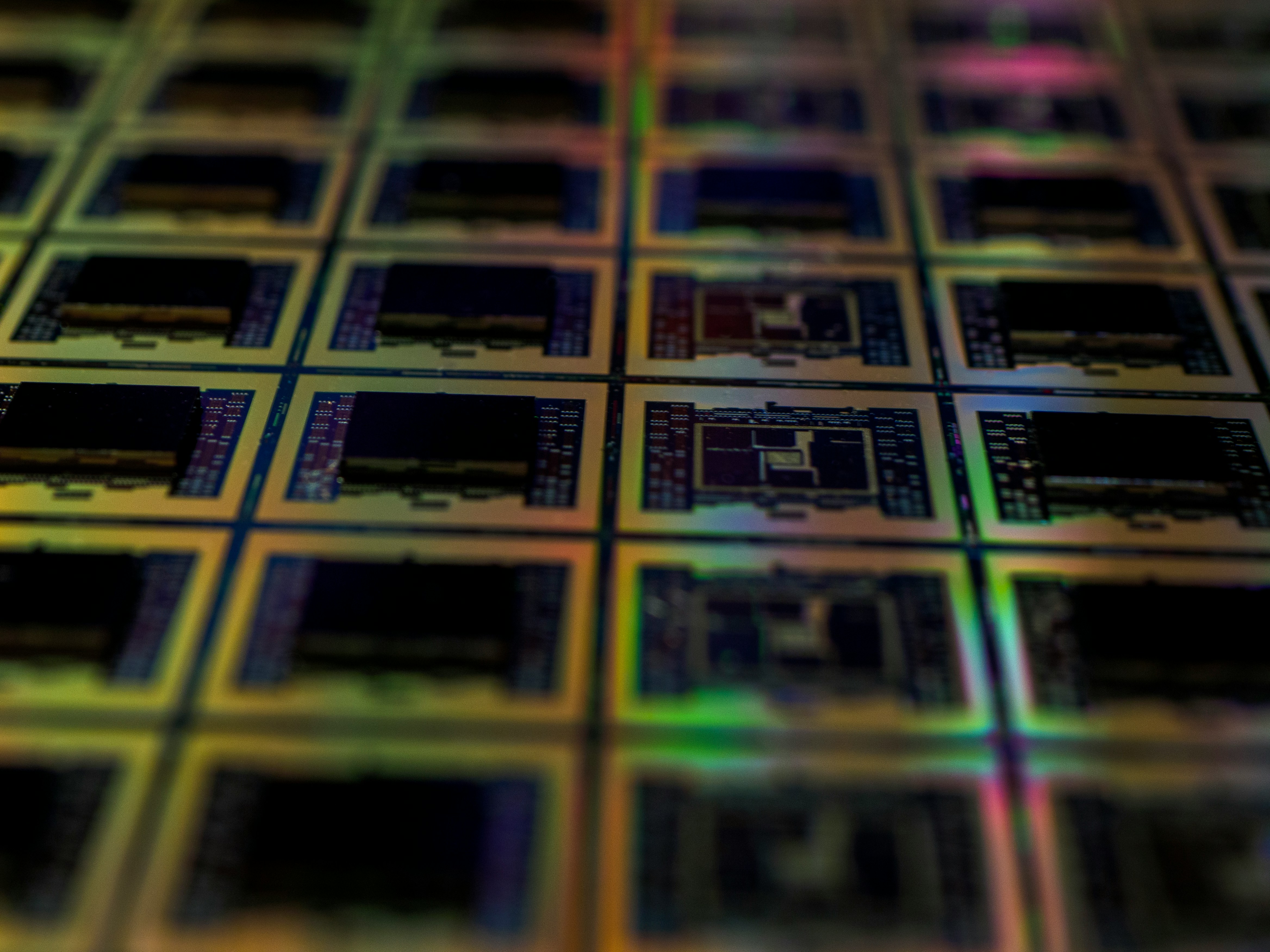

As we move into 2026, the semiconductor jobs market is in that awkward phase of being both overheated and cautious. Global chip demand is booming again, driven by AI, data centres, automotive, defence, 5G and consumer electronics. Fab capacity is set to hit record highs as new plants come online worldwide. At the same time, we are seeing: Waves of investment and hiring in some regions and companies. Restructuring and layoffs in others, as firms rebalance portfolios and chase AI margins. A deepening global skills shortage, with forecasts of major shortfalls in engineers and technicians by 2030. For the UK, the sector is small but strategically vital. The National Semiconductor Strategy, public funding and participation in European chip programmes are all aimed at building domestic capability in design, compound semiconductors and advanced manufacturing. So what does all this mean for semiconductor jobs in 2026 – and for employers trying to recruit in a brutally competitive market?