The Skills Gap in Semiconductor Jobs: What Universities Aren’t Teaching

The semiconductor industry lies at the heart of modern technology. From smartphones and data centres to autonomous vehicles, medical devices and defence systems, semiconductors power the digital age. The UK is investing heavily in semiconductor research, fabrication and talent development as part of its industrial strategy — yet employers continue to report a persistent problem:

Many graduates are not job-ready for semiconductor roles.

Despite strong academic programmes in engineering, physics and materials science, there remains a tangible skills gap between what universities teach and what semiconductor employers actually need.

This article explores that gap in depth: what universities do well, where there are consistent shortfalls, why the divide persists, what employers genuinely want, and how jobseekers can bridge the gap to build successful careers in the semiconductor sector.

Understanding the Semiconductor Skills Gap

The semiconductor skills gap refers to the mismatch between academic preparation and the applied, technical and systems-level capabilities required in modern semiconductor jobs.

Semiconductor roles span a wide range of critical activities, including:

Design and verification (digital, analogue, mixed-signal)

Process and equipment engineering

Yield enhancement and failure analysis

Test and validation

Packaging and assembly

Manufacture and production support

Metrology and inspection

Quality and reliability engineering

Despite the breadth of university programmes, many graduates lack the practical experience, industry-ready tooling knowledge and cross-disciplinary skills needed to perform effectively in these roles from day one.

Understanding this gap is the first step toward building better pathways from education to a successful semiconductor career.

What Universities Are Teaching Well

Universities provide essential foundations that matter deeply in semiconductor work.

Most graduates possess:

Strong fundamentals in physics and mathematics

Exposure to electronic devices and circuits

Knowledge of semiconductor materials and properties

Basic understanding of fabrication processes

Programming fundamentals

Analytical thinking and problem-solving skills

These fundamentals are valuable — they underpin the more advanced competencies required downstream. Employers value candidates who understand the principles of semiconductor behaviour and device physics.

However, principles alone are not enough for most semiconductor jobs.

Where the Semiconductor Skills Gap Really Appears

The gap becomes most visible when graduates step into production, R&D or applied engineering environments where theory meets complex hardware, tooling and process variation.

In the semiconductor industry, professionals are expected to:

Work with advanced fabrication equipment

Follow and write rigorous procedures

Interpret real measurement data

Solve complex, multi-variable problems

Communicate clearly with cross-functional teams

Adapt designs or processes in response to real-world constraints

These are skills that many candidates struggle to demonstrate without extended on-the-job training.

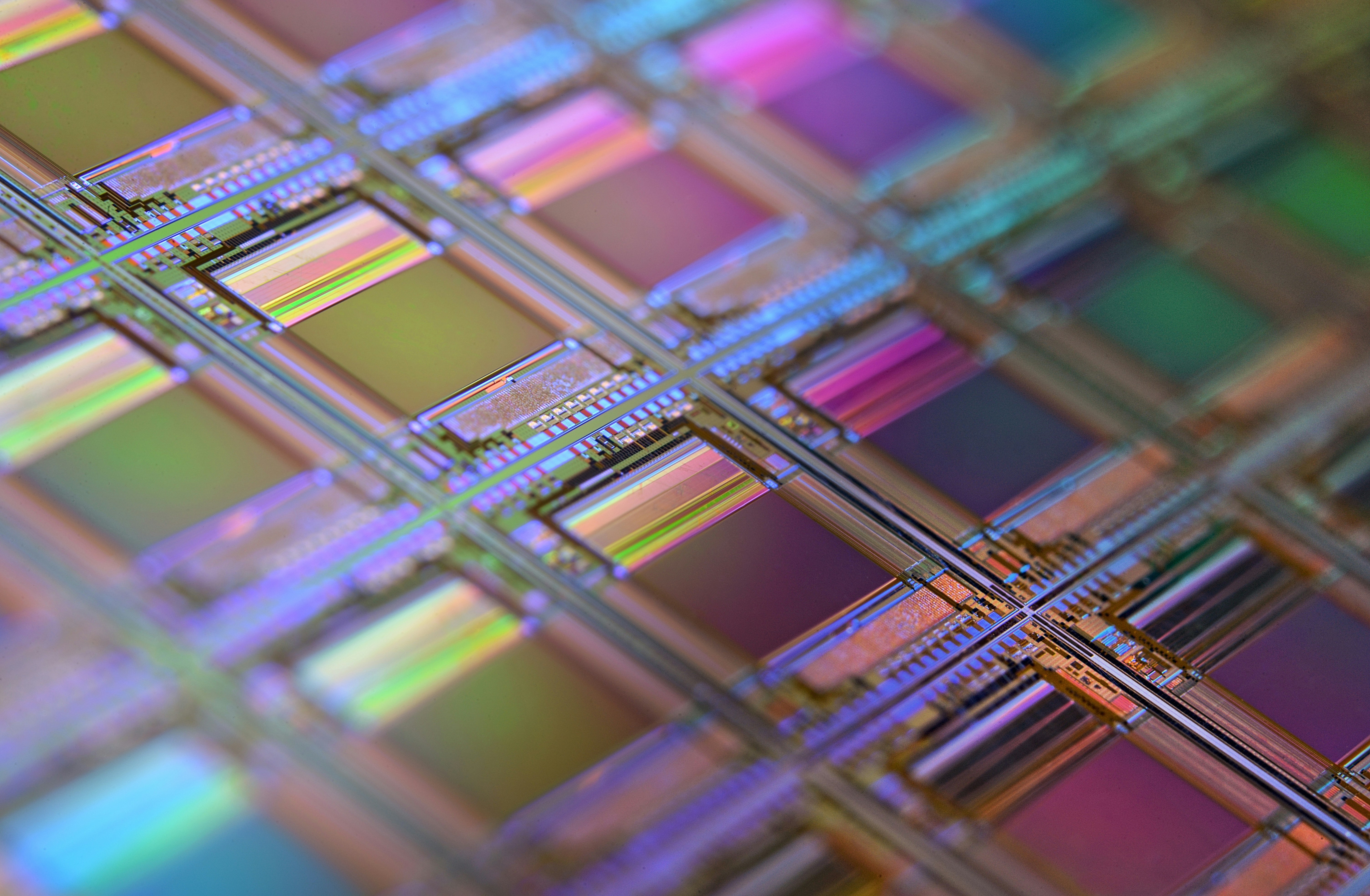

1. Hands-On Fabrication & Equipment Skills Are Often Missing

Most universities cannot simulate the environment of a semiconductor fab — yet fabrication knowledge is central to many roles.

Graduates may understand:

Oxidation, deposition, etch and lithography in theory

Device physics in controlled examples

But they often lack experience with:

Real process tools and controllers

Cleanroom protocols and discipline

Practical process sequencing

Troubleshooting equipment issues

Measuring and interpreting real outputs

This lack of practical experience makes early-career hires slower to contribute in fabrication, process support or yield improvement teams.

2. Design & Verification Tools Are Underrepresented

Semiconductor design — especially digital and mixed-signal — relies on specialised Electronic Design Automation (EDA) tools.

Universities may teach:

Fundamentals of VLSI design

Basic logic design principles

Conceptual simulation workflows

But graduates often lack experience with:

Industry-standard EDA tools for synthesis, place-and-route and verification

Version control workflows in design teams

Design for test (DFT) methodologies

Constraint-driven design practices

Timing, power and area optimisation

Employers need candidates who can navigate toolflows efficiently and think in terms of real design constraints.

3. Testing, Validation & Failure Analysis Skills Are Underdeveloped

In semiconductor work, measurement and evaluation are essential.

Graduates may lack:

Hands-on experience with test equipment

Understanding of parametric versus functional test

Ability to interpret real measurement data

Experience with debugging silicon behaviour

Knowledge of statistical process control

These skills are developed over time, but universities seldom provide realistic exposure.

4. Yield & Process Variation Realities Are Under-Taught

Textbook examples often assume idealised behaviour.

In real semiconductor production:

Variation across wafers and lots is the norm

Yield fluctuations drive commercial viability

Process windows tighten as nodes shrink

Trade-offs between performance, cost and reliability are constant

Graduates may understand concepts, but lack the ability to apply them under noisy, real-world conditions that matter to fabs and design houses alike.

5. Cross-Disciplinary Integration Is Rarely Emphasised

Semiconductor work requires collaboration across disciplines:

Device physics

Process engineering

Circuit design

Test and validation

Systems architecture

Software and automation

Universities often teach these subjects separately, leaving graduates unprepared to integrate knowledge across domains — a critical competency in real teams.

Employers look for professionals who can bridge gaps between design, manufacturing and quality engineering.

6. Software & Automation Skills Are Increasingly Essential

Modern semiconductor environments rely on automation, data analysis, scripting and software tools for:

Equipment control

Yield analytics

Statistical process control (SPC)

Machine learning applied to defect patterns

Test automation

Yet many graduates lack experience in:

Python or relevant scripting

Data pipelines for measurement and analytics

Automation frameworks in production environments

These capabilities are increasingly expected even in roles traditionally seen as hardware-focused.

7. Communication & Operational Skills Are Underdeveloped

Semiconductor professionals work within complex, safety-sensitive, high-cost environments.

Graduates often struggle with:

Documenting procedures clearly

Writing actionable reports

Communicating with multidisciplinary teams

Prioritising issues under time and cost pressure

Academic assessment often emphasises individual technical achievement rather than teamwork, documentation and operational discipline — leaving graduates underprepared for industry expectations.

Why Universities Struggle to Close the Gap

The semiconductor skills gap is structural, not negligent.

Fab Environments Are Costly & Restricted

Cleanrooms and advanced fab equipment are expensive and not practical to replicate at scale in university labs.

Tools & Platforms Evolve Quickly

EDA toolchains and fabrication technologies change faster than academic programmes can update.

Resource & Safety Constraints

Simulating production constraints safely for students is difficult and costly.

Assessment Practicalities

It is easier to assess theoretical competence than real-world applied systems performance.

What Employers Actually Want in Semiconductor Jobs

Across the semiconductor industry, employers prioritise applied, production-ready capability.

They look for candidates who can:

Work comfortably with real measurements

Understand process and equipment behaviours

Contribute to design and test workflows

Communicate with cross-functional teams

Learn quickly on the job

Degrees provide credibility. Applied capability in real environments secures employment.

How Jobseekers Can Bridge the Semiconductor Skills Gap

The skills gap is bridgeable with targeted preparation and experiential learning.

Seek Applied Experience

Internships, industrial placements, research collaborations with industry partners or lab placements provide exposure to real tools and workflows.

Learn Industry Tools

Familiarise yourself with EDA toolchains, measurement platforms and version control workflows.

Strengthen Data & Automation Skills

Build proficiency in scripting, data handling and automation — skills increasingly vital in semiconductor work.

Study Real-World Variation

Practice with datasets that include variation, noise and real measurement artefacts.

Build Cross-Disciplinary Projects

Work on problems that integrate design, process and test considerations.

Develop Communication & Documentation Skills

Practice writing clear, actionable reports and communicating with diverse stakeholders.

The Role of Employers & Job Boards

Bridging the semiconductor skills gap requires collaboration across academia and industry.

Employers benefit from:

Clear competency frameworks

Structured entry-level programmes

Mentorship and on-the-job training opportunities

Specialist platforms like Semiconductor Jobs help by:

Clarifying real-world employer requirements

Educating jobseekers on practical skills

Connecting candidates with relevant UK opportunities

As the semiconductor sector grows, skills-based hiring will increasingly outweigh academic credentials alone.

The Future of Semiconductor Careers in the UK

Demand for semiconductor professionals will continue to grow as the UK invests in:

Advanced research and fabrication facilities

Design houses and IP development

Test, validation and reliability engineering

Data analytics and automation in manufacturing

Universities will adapt, but the pace of industrial change means applied skills will remain in high demand.

In the meantime, the most successful semiconductor professionals will be those who:

Learn continuously

Build experience with real tools and workflows

Think across domains

Communicate effectively