:quality(80))

The Ultimate Assessment-Centre Survival Guide for Semiconductor Jobs in the UK

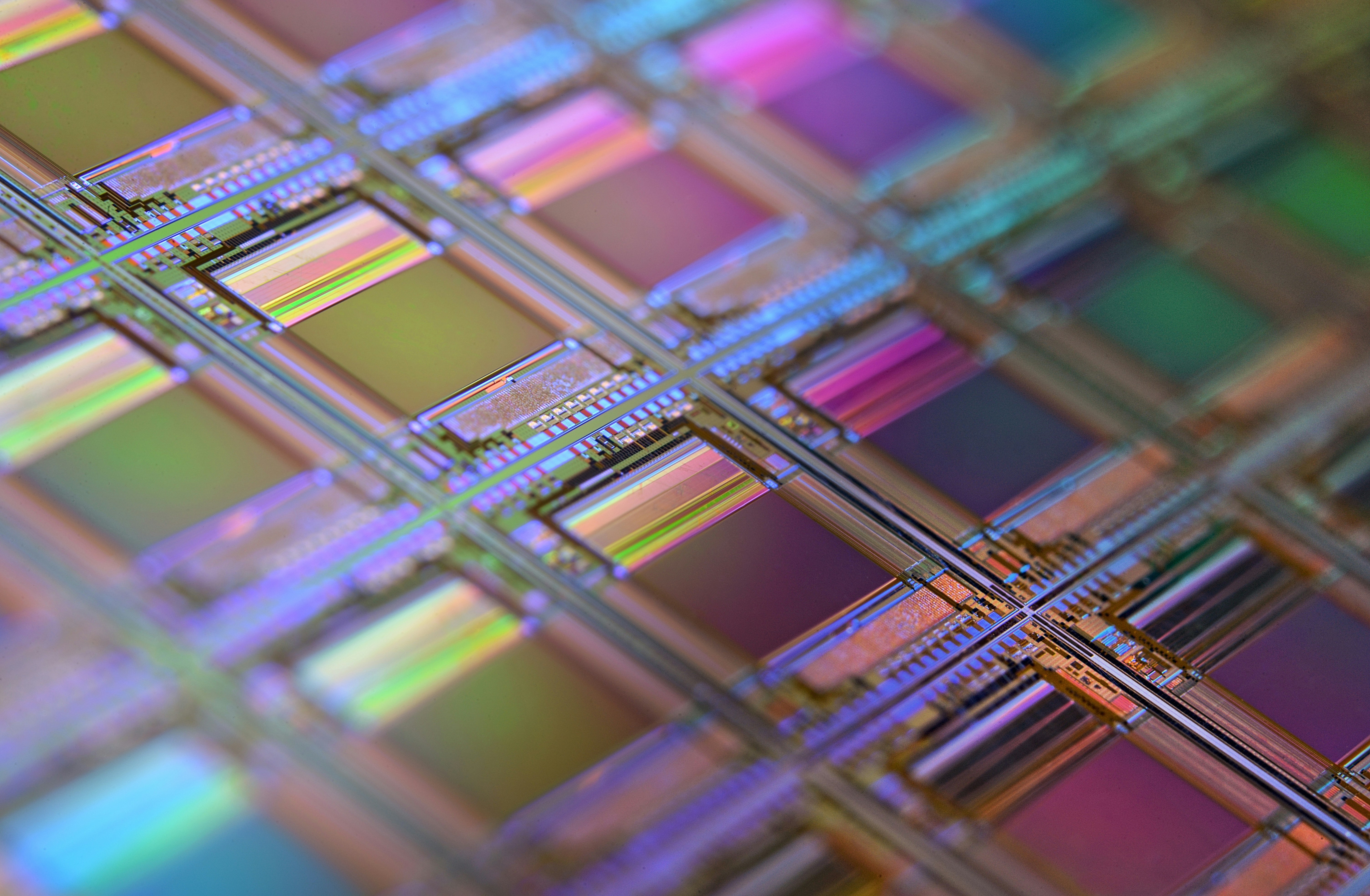

Assessment centres for semiconductor positions in the UK replicate the precision and innovation required in chip design and fabrication environments. Through psychometric assessments, hands-on fab process simulations, yield-improvement group exercises, case studies, and interviews, recruiters evaluate your technical expertise, analytical rigour, and collaboration skills. Whether you specialise in process engineering, device physics or test and validation, this guide will help you navigate every stage and secure your next role in the semiconductor industry.

Why Assessment Centres Matter for Semiconductor Roles

Semiconductor roles demand meticulous attention to detail, deep technical knowledge, and the ability to optimise complex processes. Assessment centres allow employers to assess:

Process proficiency: Your understanding of wafer fab steps—lithography, etch, deposition and CMP.

Data analysis: Interpreting yield maps, defect distributions and process control charts.

Problem-solving: Root-cause analysis and corrective action design to improve yield.

Team collaboration: Working cross-functionally with design, equipment and quality teams.

Excelling across these activities—from semiconductor psychometric tests UK to group yield workshops—demonstrates you’re ready to contribute to cutting-edge semiconductor manufacturing.

Pre-Centre Preparation

Begin your preparation 4–6 weeks before the assessment centre:

Research the company and technology

Identify their fabrication node, materials (Si, SiGe, GaN) and packaging technologies.

Review recent patents, white papers and process improvements announced.

Clarify the format

Confirm expected exercises: psychometric tests, process simulations, data analysis tasks, group workshops, case studies and interviews.

Request a detailed agenda from HR if not provided.

Refresh core technical knowledge

Wafer fabrication steps, PVD/CVD processes, photolithography fundamentals and cleanroom protocols.

Statistical process control (SPC), Six Sigma basics and yield management concepts.

Practice hands-on simulations

Use virtual fab tools or training modules to rehearse process recipe adjustments and defect analysis.

Conduct timed SPC chart interpretation drills with sample datasets.

Mock group exercises

Collaborate on yield improvement scenarios: define metrics, identify root causes and propose action plans.

Prepare short presentations of your findings and recommendations.

Excelling in Psychometric Assessments

Psychometric tests offer objective measures of your reasoning and behavioural styles—essential in high-stakes fab environments.

Common Formats

Numerical Reasoning: Analyse SPC charts, defect density tables and equipment performance metrics (20–30 mins).

Logical Reasoning: Sequence process steps or identify patterns in defect occurrence (15–20 mins).

Verbal Reasoning: Comprehend technical method statements or safety guidelines (20–25 mins).

Situational Judgement: Choose best actions in equipment failure or quality audit scenarios (15–20 mins).

Preparation Tips

Use industry-focused practice tests where available.

Review statistics fundamentals: mean, sigma levels, control limits.

Simulate timed sessions to improve speed and accuracy.

Process Simulation and Data Analysis Tasks

Hands-on exercises assess your ability to troubleshoot and optimise semiconductor processes.

Typical Exercises

Adjust a lithography process recipe to reduce overlay error and note impact on critical dimension.

Analyse defect map data to identify hotspots and recommend process modifications.

Optimise a wafer clean process by interpreting endpoint detection graphs.

Best Practices

Clarify objectives: Confirm target yield, defect thresholds and equipment capabilities.

Document assumptions: Record baseline data, tool parameters and environmental conditions.

Analyse methodically: Use root-cause tools—fishbone diagrams, five whys and Pareto charts.

Recommend clearly: Present actionable changes, expected yield gains and risk assessments.

Collaborative Yield-Improvement Workshops

Group workshops simulate cross-functional collaboration to boost fab performance.

Scenario Examples

Reducing line-edge roughness through combined lithography and etch adjustments.

Improving test-site yield by analysing probe card performance and wafer warpage.

Implementing inline metrology feedback to control via aspect ratio.

Stand-Out Strategies

Start by defining success metrics: yield targets, defect densities and cycle times.

Assign roles: process lead, data analyst, quality coordinator and presenter.

Encourage data-driven debate using SPC outputs and defect statistics.

Conclude with a clear implementation plan: action items, timelines and responsibility matrix.

Case Studies and Presentations

Case studies assess your ability to propose end-to-end solutions for semiconductor challenges.

Presentation Structure

Context: Describe the fab environment, node specifications and critical KPIs.

Analysis: Outline data findings, root-cause insights and process correlations.

Solution: Recommend process changes, tool adjustments or metrology enhancements.

Implementation: Detail phases, resource requirements and monitoring plans.

Tips for Delivery

Use clear charts: SPC graphs, defect maps and process flow diagrams.

Avoid jargon: explain technical terms for mixed audiences.

Prepare for questions: anticipate queries on cost, risk and cross-tool impacts.

Individual Interviews: Technical & Behavioural

Interviews explore your depth of semiconductor expertise and collaboration style.

Technical Interview Focus

Discuss past projects: process optimisation, defect reduction or equipment qualification.

Troubleshooting scenarios: yield drop investigations or tool calibration errors.

Theory deep-dive: device physics questions—MOSCAP operation, leakage mechanisms or dielectric breakdown.

Behavioural Interview Focus

Use the STAR method:

Situation: A significant yield excursion during ramp-up.

Task: Your role—process engineer, root-cause investigator.

Action: Steps taken—data collection, cross-functional meetings, process trial implementation.

Result: Quantify improvements—yield recovery, defect rate reduction or cycle time savings.

Lunch Etiquette & Informal Networking

Informal breaks reveal your professionalism and cultural fit.

Lunch Best Practices

Arrive punctually, follow polite table manners and minimise contamination risks.

Engage in inclusive topics: semiconductor trends, favourite labs or hobbies.

Offer to share condiments or insights on recent technological advances.

Keep device use minimal; stay present in discussions.

Networking Pointers

Ask assessors about their experiences in wafer fab and device reliability.

Discuss emerging areas: EUV lithography, 3D integration or advanced packaging.

Exchange LinkedIn details to follow up and stay connected.

Managing Stress and Sustaining Focus

Semiconductor assessment centres are intense—plan for resilience.

Ensure 7–8 hours’ sleep and a nutritious breakfast.

Take micro-breaks: stretch, breathe or grab fresh air outside the fab.

Stay hydrated and carry a light snack to maintain energy.

Use positive self-talk: recall previous successful process improvements.

Post-Centre Follow-Up & Reflection

A thoughtful follow-up emphasises your professionalism.

Thank-you emails: Personalise to each assessor, referencing specific exercises or discussions.

Self-review: Note areas of strength and opportunities for development—process expertise, data analysis or teamwork.

Continued engagement: Share relevant industry articles or white papers on LinkedIn to stay top of mind.

Conclusion

Excelling at a semiconductor assessment centre in the UK demands precise technical knowledge, analytical rigour and cross-functional collaboration. By mastering psychometric assessments, process simulations, yield workshops, case studies and interviews—and by conducting yourself professionally during informal interactions—you’ll demonstrate the comprehensive skill set needed to drive semiconductor innovation.

Call to Action

Ready to accelerate your semiconductor career? Visit Semiconductor Jobs to explore the latest opportunities, access expert resources and subscribe to personalised job alerts. Take the next step towards shaping the future of chip technology—today!

FAQ

Q1: When should I start preparing for a semiconductor assessment centre? Begin 4–6 weeks beforehand to review fab processes, practise simulations and conduct mock data analyses.

Q2: Which fabrication steps are most commonly assessed? Lithography, etch, deposition (PVD/CVD), CMP and process control techniques.

Q3: How can I demonstrate robust data analysis skills? Use SPC charts, Pareto analysis and root-cause tools, explaining your methodology clearly.

Q4: Are communication skills evaluated during technical rounds? Yes—clear, concise explanation of complex processes and data is crucial.

Q5: What’s the ideal timeline for follow-up? Send personalised thank-you emails within 24–48 hours and connect on LinkedIn for continued engagement.