Neurodiversity in Semiconductor Careers: Turning Different Thinking into a Superpower

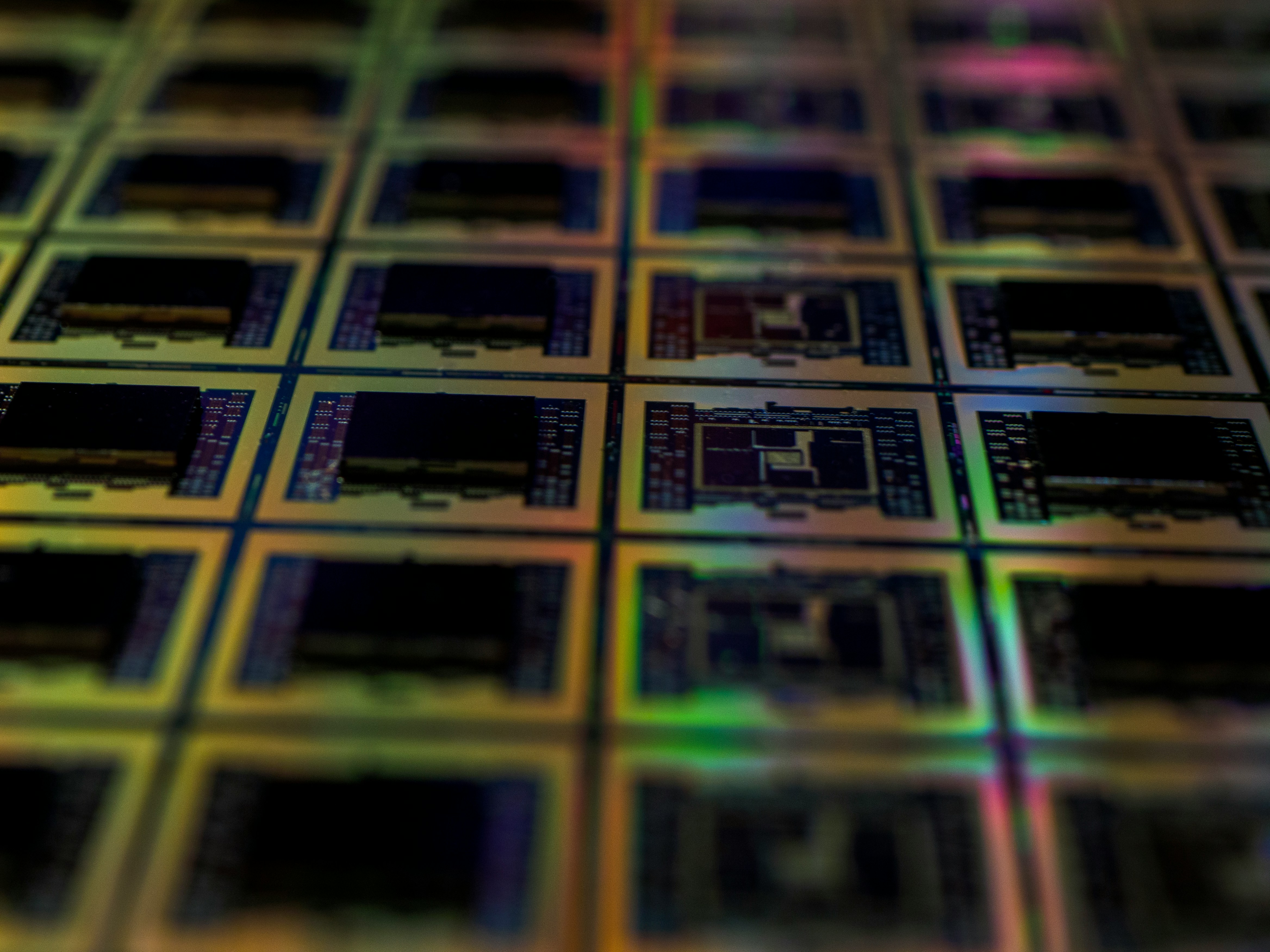

Semiconductors sit quietly at the heart of everything: phones, cars, medical devices, satellites, data centres & everyday appliances. Behind every chip are people designing circuits, running fabs, testing wafers, modelling devices & solving problems most users never see. Those people are not all “textbook” engineers – & that’s a good thing. If you’re neurodivergent (for example living with ADHD, autism or dyslexia), you may have been told your brain is “too distracted”, “too literal” or “too disorganised” for a high-precision, high-reliability industry. In reality, many of the traits that made school or traditional offices hard can be huge strengths in semiconductor work: intense focus on detail, pattern-spotting in test data, creative thinking around yield & process issues. This guide is written for semiconductor job seekers in the UK. We’ll cover: What neurodiversity means in a semiconductor context How ADHD, autism & dyslexia strengths map to chip & fab roles Workplace adjustments you can ask for under UK law How to talk about your neurodivergence in applications & interviews By the end, you should have a clearer sense of where you might thrive in the semiconductor industry – & how to turn “different thinking” into a genuine career advantage.