Related Jobs

View all jobsProcess Engineer

Process Engineer

Process Engineer

Process Engineer

Process Engineer

Subscribe to Future Tech Insights for the latest jobs & insights, direct to your inbox.

Industry Insights

Discover insightful articles, industry insights, expert tips, and curated resources.

Semiconductor Recruitment Trends 2025 (UK): What Job Seekers Need To Know About Today’s Hiring Process

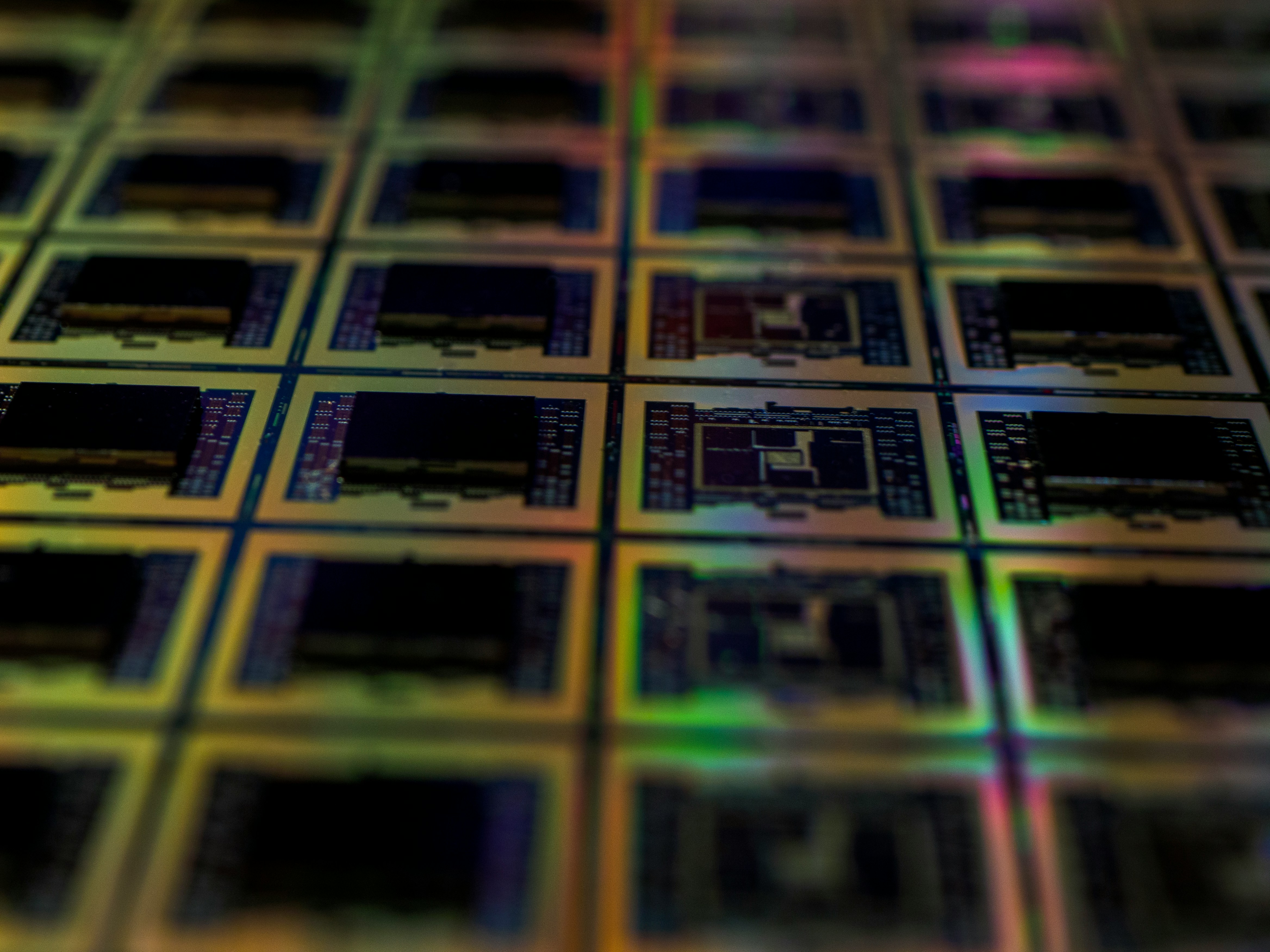

Summary: UK semiconductor hiring has shifted from credentials & tool lists to capability‑driven evaluation that emphasises shipped silicon, yield/reliability gains, verification coverage, DFM/DFT maturity, robust bring‑up, safe/efficient fab operations and measurable business impact (PPM, YMS wins, time‑to‑yield, test cost, opex). This guide explains what’s changed, what to expect in interviews and how to prepare—especially for RTL/ASIC/SoC, analog/mixed‑signal/RF, verification, physical design, DFT/ATPG, product/test, failure analysis & reliability, process/device, equipment/maintenance, EHS, supply chain & operations roles. Who this is for: Digital design & verification engineers, PD & timing closure, analog/mixed‑signal/RF designers, DFT/ATPG/BIST, STA/PDN/SI/PI specialists, product/test engineers (ATE/DFT), yield/reliability & FA, device/process (FEOL/BEOL), equipment & facilities, EHS/compliance, supply‑chain/outsourcing (OSAT/Foundry), and programme/product managers across the UK semicon ecosystem.

Why Semiconductor Careers in the UK Are Becoming More Multidisciplinary

Semiconductors power everything from smartphones to advanced computing to automotive systems. The UK semiconductor industry is expanding amid renewed global interest in chip sovereignty and lithography innovation. But the demands on professionals in semiconductor roles are shifting too. Today, semiconductor careers are no longer limited to clean-room engineers or circuit layout designers. Because chips affect data privacy, critical infrastructure, supply security and performance constraints, careers in this sphere are becoming deeply multidisciplinary. Knowledge in law, ethics, psychology, linguistics & design is increasingly relevant to semiconductor engineering. In this article, we’ll explore why semiconductor careers in the UK are becoming more multidisciplinary, how those allied fields intersect with semiconductor work, and what job-seekers & employers can do to adapt.

Semiconductor Team Structures Explained: Who Does What in a Modern Semiconductor Department

The semiconductor industry underpins nearly all modern electronics—from smartphones and servers to sensors, automotive control systems, artificial intelligence accelerators, and more. In the UK it plays a growing role in chip design, MEMS, optoelectronics, and foundry services. Building performant, reliable, competitive semiconductor products requires tightly coordinated teams that span design, fabrication, testing, packaging, yield engineering, reliability, verification, quality, and supply chain. If you’re applying for semiconductor roles via SemiconductorJobs.co.uk or building a semiconductor team, this guide will help you understand the typical roles, how they collaborate across the product lifecycle, what skills UK employers expect, salary expectations, common challenges, and how to structure teams to succeed.