Semiconductor Manufacturing vs. Chip Design vs. Embedded Systems: Which Path Should You Choose?

The semiconductor industry underpins virtually every aspect of modern technology—smartphones, computers, autonomous vehicles, high-performance computing, IoT devices, and more. As our world becomes increasingly digital, demand for cutting-edge integrated circuits (ICs) and chips continues to soar, driving significant growth in semiconductor jobs. If you’ve been exploring opportunities on www.semiconductorjobs.co.uk, you may notice roles spanning Semiconductor Manufacturing, Chip (IC) Design, and Embedded Systems. While they’re all integral to producing and utilising advanced semiconductors, each field focuses on distinct phases and processes within the semiconductor ecosystem.

Which path should you choose if you’re passionate about pushing technology’s limits? In this in-depth article, we’ll define Semiconductor Manufacturing, Chip Design, and Embedded Systems, clarifying their core responsibilities, overlapping vs. distinctive skill sets, salary ranges, and real-world applications. Whether you’re a materials scientist, electrical engineer, software developer, or hardware enthusiast, understanding these subfields will help you chart a career that aligns with your interests and strengths—ultimately contributing to the next wave of innovation in electronic devices and beyond.

1. Defining the Fields

1.1 Semiconductor Manufacturing

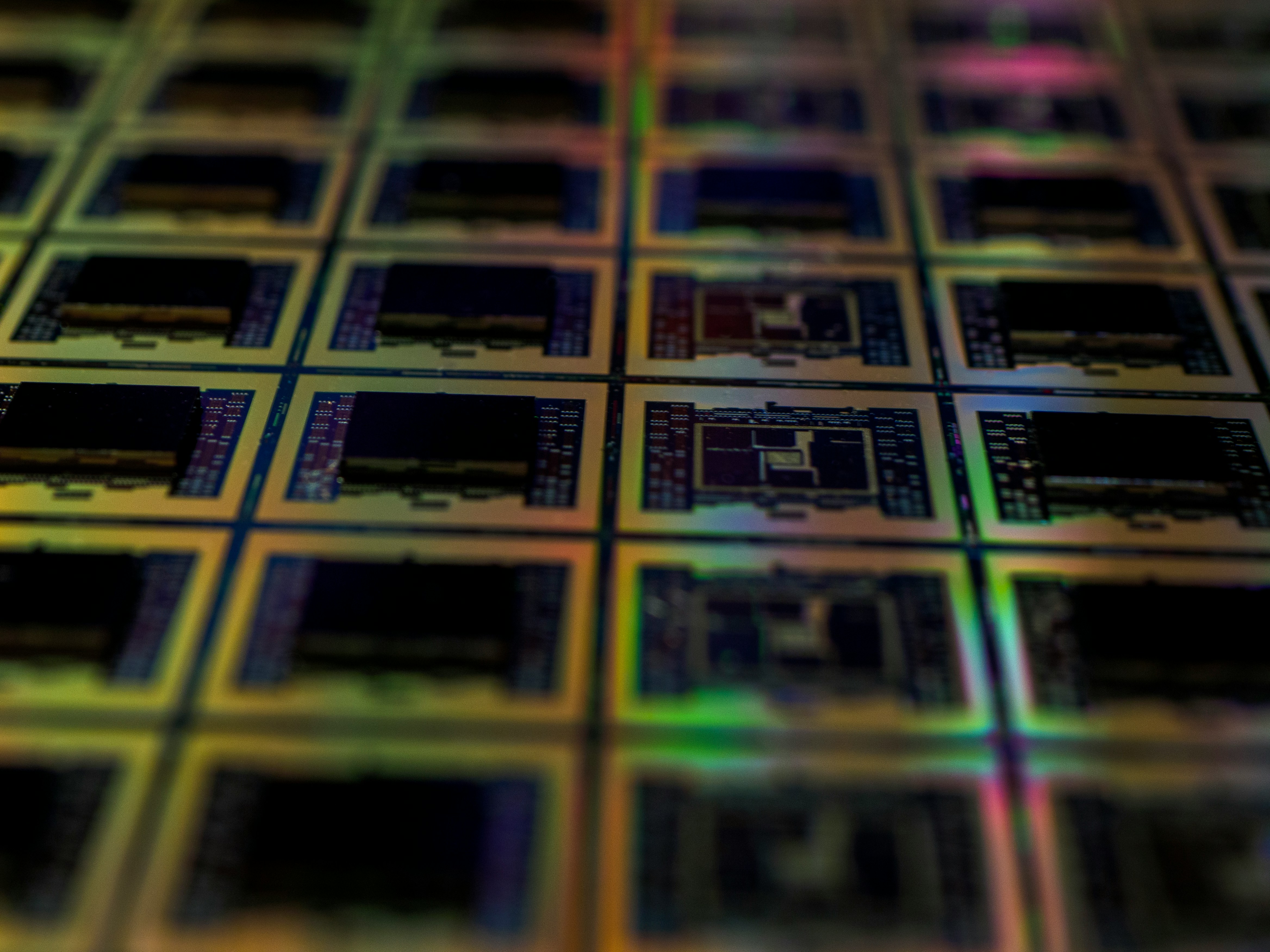

Semiconductor Manufacturing—often referred to as chip fabrication or front-end/back-end processing—concerns the production of integrated circuits on silicon wafers (or sometimes alternative materials like GaN, SiC, or compound semiconductors). This highly specialised process involves:

Wafer Fabrication: Depositing and patterning thin films, doping materials, and building transistors or other active components layer by layer.

Lithography & Etching: Using photolithography to create circuit patterns, then etching away unwanted material.

Doping & Diffusion: Introducing impurities into silicon to alter conductivity characteristics and form p-n junctions.

Packaging & Testing: Encasing the die in protective packages, attaching leads or balls, and verifying performance under temperature/cycle tests.

Professionals in semiconductor manufacturing ensure that each production step meets microscopic precision tolerances. Yield and throughput are paramount, as small defects can ruin entire wafers or hamper device reliability. This field often suits materials scientists, process engineers, equipment technicians, and quality control experts looking to push boundaries in nanofabrication.

1.2 Chip (IC) Design

While Semiconductor Manufacturing deals with physically producing chips, Chip (IC) Design focuses on conceptualising, architecting, and verifying integrated circuits before they ever reach the fab. This includes:

Front-End Design: High-level architectural decisions, writing Register Transfer Level (RTL) code (e.g., in Verilog or VHDL), simulating logic to ensure functional correctness.

Verification & Validation: Checking that the design meets specifications and handles corner cases, using testbenches, formal methods, or coverage-driven verification.

Synthesis & Place-and-Route (Backend Design): Translating RTL into gate-level netlists, optimising timing, power, and area, then physically placing and routing the logic on a chip layout.

EDA Tools Mastery: Proficiency with tools from companies like Cadence, Synopsys, or Mentor Graphics to handle large-scale IC design complexities.

Chip designers specialise in microarchitecture (CPUs, GPUs, SoCs), or specific functionalities (analog circuits, RF transceivers, power management). If you enjoy problem-solving at the intersection of electrical engineering, computer architecture, and software tools, IC design could be your calling.

1.3 Embedded Systems

Embedded Systems typically involve deploying software and hardware on microcontrollers (MCUs) or systems-on-chip (SoCs) to control devices in consumer electronics, automotive ECUs, IoT sensors, industrial controllers, and more. Although not exclusively about semiconductors, embedded systems rely heavily on custom or off-the-shelf chips to run dedicated firmware.

Core aspects of Embedded Systems:

Firmware Development: Writing low-level code (often in C/C++) that interacts directly with registers, peripheral drivers, or real-time operating systems (RTOS).

Hardware-Software Co-Design: Selecting the right microprocessor/microcontroller or SoC, configuring memory and I/O, balancing performance and power constraints.

Integration & Testing: Ensuring that the embedded software functions reliably under resource-limited or safety-critical conditions, often with real-time deadlines.

Communication & Interfaces: Managing protocols such as I2C, SPI, UART, CAN, or Ethernet, enabling devices to sense, actuate, and communicate data seamlessly.

Embedded systems may not require you to fabricate silicon, but a deep understanding of chip capabilities is crucial. If you enjoy bridging low-level software with hardware constraints—sometimes within extremely tight power or size envelopes—an embedded systems role could offer exciting challenges.

2. Overlapping vs. Distinctive Skill Sets

While Semiconductor Manufacturing, Chip Design, and Embedded Systems each occupy different segments of the semiconductor value chain, they share a foundation in electronics and problem-solving but differ in day-to-day focus.

2.1 Overlapping Skills

Electronics & Circuit Fundamentals:

All roles require understanding basic transistor operation, circuit topologies, or digital logic concepts.

Quality & Reliability Mindset:

Ensuring chips or embedded devices function reliably is universal across manufacturing yields, design specs, and field operation.

Analytical Thinking & Collaboration:

These are complex, multidisciplinary fields where cross-functional teamwork (process engineers, design engineers, software developers) is vital.

Industry Standards & Regulations:

From safety compliance (e.g., ISO, IPC standards) to EDA licensing or automotive A-SPICE guidelines, professionals typically navigate stringent requirements.

2.2 Distinctive Skills

Semiconductor Manufacturing

Process Engineering & Nanofabrication: Mastering lithography, deposition (CVD, PVD), doping, and etch techniques.

Equipment Maintenance & Yield Analysis: Troubleshooting sophisticated fab tools (steppers, ion implanters), driving yield improvements through data analytics.

Materials Science & Cleanroom Protocols: Handling wafer contamination control, chemical solutions, wafer bonding, or advanced packaging.

Chip (IC) Design

RTL Coding & Digital Logic: Writing Verilog/VHDL, concurrency, synchronous vs. asynchronous logic, pipeline design.

EDA Tools & Flows: Synthesis, timing closure, power/area tradeoffs, place-and-route, verifying correctness with testbenches (SystemVerilog, UVM).

Domain-Specific Architectures: CPU pipelines, DSP blocks, memory controllers, interfacing with analog IP or standard libraries.

Embedded Systems

Firmware Programming: Low-level code, real-time OS, interrupt handling, driver development.

Microcontroller & SoC Architecture: Familiarity with ARM Cortex, RISC-V, or proprietary architectures, memory mapping, clock configuration.

Product Integration & Testing: Ensuring hardware meets constraints, debugging with JTAG, logic analyzers, or in-circuit emulators, final validation under real conditions.

3. Typical Job Titles and Responsibilities

When browsing www.semiconductorjobs.co.uk, you’ll see roles varying from front-end design engineers to wafer fabrication process engineers. Here’s a breakdown:

3.1 Semiconductor Manufacturing Roles

Process Engineer

Focus: Overseeing deposition, etching, or lithography steps, optimising recipes for yield and throughput.

Responsibilities: Monitoring wafer runs, troubleshooting tool issues, analysing defects, collaborating with yield engineers to refine process windows.

Equipment Maintenance Technician / Engineer

Focus: Maintaining and calibrating complex fab machines (steppers, ion implanters, etchers).

Responsibilities: Performing preventative maintenance, diagnosing mechanical or electronic malfunctions, minimising downtime.

Packaging / Assembly Engineer

Focus: Handling back-end processes—dicing, wire bonding, encapsulation—ensuring robust packaging for final IC reliability.

Responsibilities: Selecting materials (lead frames, underfill), verifying package thermal/mechanical performance, transferring processes to high-volume manufacturing.

3.2 Chip (IC) Design Roles

Front-End Digital Design Engineer

Focus: RTL development (Verilog/VHDL), creating logic blocks for microprocessors, SoCs, or FPGA designs.

Responsibilities: Writing code, synthesising designs, running static timing analysis, ensuring functionality meets specs, coordinating with verification teams.

Verification Engineer

Focus: Ensuring correctness of complex IC designs via simulation, testbenches, or formal verification.

Responsibilities: Creating coverage-driven tests, debugging waveforms, implementing UVM frameworks, ensuring corner cases are tested.

Physical Design / Backend Engineer

Focus: Converting gate-level netlists into final layouts, performing floorplanning, placement, routing, and sign-off checks.

Responsibilities: Meeting timing, power, and area targets, verifying design rule checks (DRC), collaborating with front-end engineers to close constraints.

3.3 Embedded Systems Roles

Firmware Engineer (Embedded)

Focus: Writing low-level software on microcontrollers (ARM Cortex, AVR, PIC) for consumer electronics, automotive ECUs, or industrial controls.

Responsibilities: Configuring peripherals (PWM, ADC), implementing communication stacks (CAN, I2C), debugging hardware-software interactions, ensuring real-time performance.

Hardware-Software Integration Engineer

Focus: Selecting or designing PCBs, ensuring microprocessors or SoCs interface with sensors/displays, bridging software drivers with hardware resources.

Responsibilities: Schematic reviews, board bring-up, evaluating component trade-offs (power, cost, performance), coding hardware abstraction layers (HAL).

IoT Systems Developer

Focus: Building connected embedded devices with wireless modules (Wi-Fi, Bluetooth, LoRa), cloud integration, or edge computing capabilities.

Responsibilities: Implementing secure boot, OTA updates, data encryption, balancing battery life and performance constraints, collaborating on sensor data analytics.

4. Salary Ranges and Demand

While actual compensation depends on experience, location, and company size (start-ups vs. large corporations), below are approximate UK-based ranges:

4.1 Semiconductor Manufacturing Roles

Process Engineer

Entry-level: £28,000–£40,000

Mid-level: £40,000–£60,000

Senior: £60,000–£80,000+

Equipment Maintenance Engineer/Technician

Range: £25,000–£45,000+ (depending on shift differentials, expertise)

Packaging / Assembly Engineer

Entry-level: £28,000–£38,000

Mid-level: £38,000–£55,000

Senior/Lead: £55,000–£75,000+

4.2 Chip (IC) Design Roles

Front-End Digital Design Engineer

Entry-level: £30,000–£45,000

Mid-level: £45,000–£65,000

Senior/Principal: £65,000–£100,000+

Verification Engineer

Entry-level: £30,000–£45,000

Mid-level: £45,000–£70,000

Senior/Lead: £70,000–£110,000+

Physical Design / Backend Engineer

Range: £40,000–£100,000+

Senior roles, especially in advanced nodes (5nm, 3nm), can exceed £120,000.

4.3 Embedded Systems Roles

Firmware Engineer (Embedded)

Entry-level: £28,000–£40,000

Mid-level: £40,000–£60,000

Senior: £60,000–£80,000+

Hardware-Software Integration Engineer

Range: £35,000–£75,000+

Complex system integrators or lead positions may go beyond £80,000.

IoT Systems Developer

Entry-level: £30,000–£45,000

Mid-level: £45,000–£65,000

Senior/Architect: £65,000–£90,000+

5. Real-World Examples

5.1 Semiconductor Manufacturing in Action

Leading-Edge Logic ChipsA major fab processes 300mm wafers at 5nm node technology for smartphone SoCs. A Process Engineer fine-tunes lithography exposure parameters, doping concentration, and CMP (chemical mechanical planarisation) steps to maximise transistor performance and yield, ensuring minimal power leakage.

Power Semiconductor DevicesAn automotive supplier invests in SiC MOSFET production for electric vehicle inverters. A Packaging Engineer designs new modules with better heat dissipation, enabling high voltages and reduced conduction losses, leading to extended EV range.

5.2 Chip (IC) Design in Action

SoC for AI AcceleratorsA start-up creates a custom SoC that offloads neural network computations. A Front-End Digital Design Engineer codes the accelerator’s matrix multiply logic in Verilog, while a Verification Engineer sets up testbenches to confirm correctness across corner cases. On tape-out, the chip surpasses performance targets for ML inference.

Analog/Mixed-Signal ICA consumer electronics giant develops a new audio codec chip. The Analog Design Team crafts low-noise amplifiers and DAC/ADC blocks, while the digital portion handles data streams and control logic. Collaborating with physical design ensures the final layout meets noise and crosstalk constraints.

5.3 Embedded Systems in Action

Automotive ECU DevelopmentA Tier 1 supplier designs an engine control unit using a 32-bit microcontroller. The Firmware Engineer codes real-time ignition timing and fuel injection control routines, verifying compliance with automotive safety standards (ISO 26262). This leads to more efficient, lower-emission vehicles.

Smart Home DevicesA home automation firm launches a connected thermostat powered by an ARM Cortex-M SoC. An IoT Systems Developer integrates wireless modules (Wi-Fi, Zigbee), ensuring seamless app connectivity, over-the-air firmware updates, and minimal standby power consumption.

6. Which Path Should You Choose?

Choosing among Semiconductor Manufacturing, Chip Design, or Embedded Systems depends on your technical inclinations, career aspirations, and the environment you thrive in:

Semiconductor Manufacturing

If you enjoy materials science, nanofabrication, or working in high-tech cleanrooms, a fab process or equipment engineering role can be highly satisfying.

Career Growth & Industries: Major fabs (TSMC, GlobalFoundries, Intel) or local foundries, advanced packaging/assembly houses, specialised power or sensor device producers.

Chip (IC) Design

If you’re passionate about logic design, digital/analog circuits, or verifying large-scale SoCs, designing the next generation of CPUs, GPUs, or domain-specific chips can be rewarding.

Career Growth & Industries: Leading silicon IP firms (ARM), big tech players (Apple, Google, NVIDIA), EDA tool vendors, FPGA companies, or fabless design houses (Qualcomm, Broadcom).

Embedded Systems

If bridging software and hardware intrigues you, especially in real-world products, embedded systems span automotive, IoT, consumer electronics, and more.

Career Growth & Industries: Countless product design companies, from automotive ECUs (Bosch, Continental) to smart devices (Dyson, Philips), industrial automation, or microcontroller vendors (STMicro, Microchip).

7. Tips for Breaking Into Your Chosen Field

Regardless of your target specialisation, these strategies can accelerate your career:

Academic Foundation & Internships

University Degrees: Electrical Engineering, Computer Engineering, Materials Science, or a related STEM field. Some roles may need postgraduate degrees for advanced R&D.

Internships or Co-ops: Seek placements at semiconductor fabs, IC design houses, or embedded product firms to gain hands-on experience with real projects.

Online Courses & Certifications

Semiconductor Manufacturing: Learn about wafer fab processes, yield improvement, or advanced node challenges via Coursera/edX (some courses by universities or industry consortia).

Chip Design: Explore RTL coding, EDA flows (Cadence, Synopsys) or take FPGA-based courses.

Embedded Systems: Master microcontroller programming (C, C++), real-time OS fundamentals, or IoT frameworks via sites like Udemy, freeRTOS tutorials, or embedded bootcamps.

Build Projects & Portfolios

FPGAs or SoC Prototypes: Implement small designs on FPGA boards (Xilinx, Intel) to show logic design proficiency.

Microcontroller Projects: Demonstrate embedded sensor fusion, motor control, or IoT connectivity.

Open-Source Contributions: Many hardware or embedded communities welcome contributions, from drivers to design files.

Networking & Conferences

Semiconductor & EDA: Attend ISSCC, Semicon, DAC (Design Automation Conference).

Embedded Systems: Explore Embedded World, Arm TechCon, or local maker fairs.

Professional Associations: Join IEEE, IET, or local semiconductor interest groups to stay updated on research and job postings.

Stay Current on Industry Trends

Moore’s Law & Beyond: Understanding scaling challenges, chiplet architectures, 3D stacking, and new materials (e.g., GaN) can stand out.

RISC-V & Open-Source Hardware: Growing momentum for open instruction set architectures.

Edge AI & HPC Trends: Shifting design priorities for AI acceleration, advanced packaging, or domain-specific SoCs in HPC or automotive.

Highlight Transferable Skills

Collaboration & Communication: Large-scale IC designs or production lines require multidisciplinary teams. Communicating effectively across teams is crucial.

Attention to Detail: Minor oversights (a mask misalignment, a gating error) can sink an entire wafer lot or chip design. Show your methodical approach.

Problem-Solving & Adaptability: The semiconductor industry evolves rapidly; eagerness to learn new tools, processes, or design paradigms is highly valued.

8. Conclusion

Semiconductor Manufacturing, Chip (IC) Design, and Embedded Systems each hold pivotal roles in creating the integrated circuits and solutions powering modern electronics. From forging transistors at the nanoscale in a high-tech fab, to architecting SoCs that drive smartphones and GPUs, to embedding software on microcontrollers for countless applications—these fields collectively shape our digital world.

Your choice depends on whether you prefer controlling every detail of wafer processing, conceptualising logic at a hardware level, or bridging hardware-software in embedded devices. Whichever path you choose, the semiconductor industry offers a dynamic career landscape with global impact—enabling faster, more efficient, and more powerful electronic systems for everything from data centres to wearable devices.

If you’re ready to dive into this cutting-edge space, explore the latest semiconductor jobs at www.semiconductorjobs.co.uk. You’ll find roles spanning wafer process engineering, advanced IC design, embedded firmware, and more. By combining strong technical fundamentals, hands-on experience, and a passion for innovation, you can play a key role in pushing technology’s frontiers and shaping tomorrow’s digital era.

About the Author:This article aims to clarify the distinctions among Semiconductor Manufacturing, Chip (IC) Design, and Embedded Systems for those exploring a career in the semiconductor sector. For more resources, job listings, and expert insights, visit www.semiconductorjobs.co.uk and find your place in this rapidly advancing industry.